Shifting the Cg’s location can be done by changing the material of the fin, lightening aspects of the model, or adding nose weight to the rocket. The second option would be to shift the Cg. Because the model V2 needs to remain scale this is not an appropriate change. Shifting the Cp down would require a change in area, either by lengthening the rocket body tube or increasing the size of the fins. The instability can be rectified two ways. The Cp for the model V2’s design has an averaged location of 163.7 mm from the datum.Īt this point in the design the Cp is higher than the Cg making the rocket unstable.

The average of the two calculations was determined to be ideal based on multiple wind tunnel tests performed for the report. Referencing a college dynamics report I wrote on rocket design the best approximation for the Cp is an average of the two methods discussed above. The Cp location for the “By Parts” method calculated to be 172.5 mm from the datum.

Note that the area of the fin is multiplied by 2 to account for both stabilizers. The total area (A t) divides the summation of the y-bar and A p, giving the solution Y-Bar. The y-bar for each part is then multiplied by the the projected area of each part (A p). Cp by parts utilizes the location of the center of mass for each part noted by y-bar measured from the bottom datum. “By Parts” is the second method of calculating the Cp. Using the equal areas calculation the Cp distance from the bottom datum is located at 154.9 mm. 201 steps were used in the second design study showing equal area to within less than 0.25% difference.

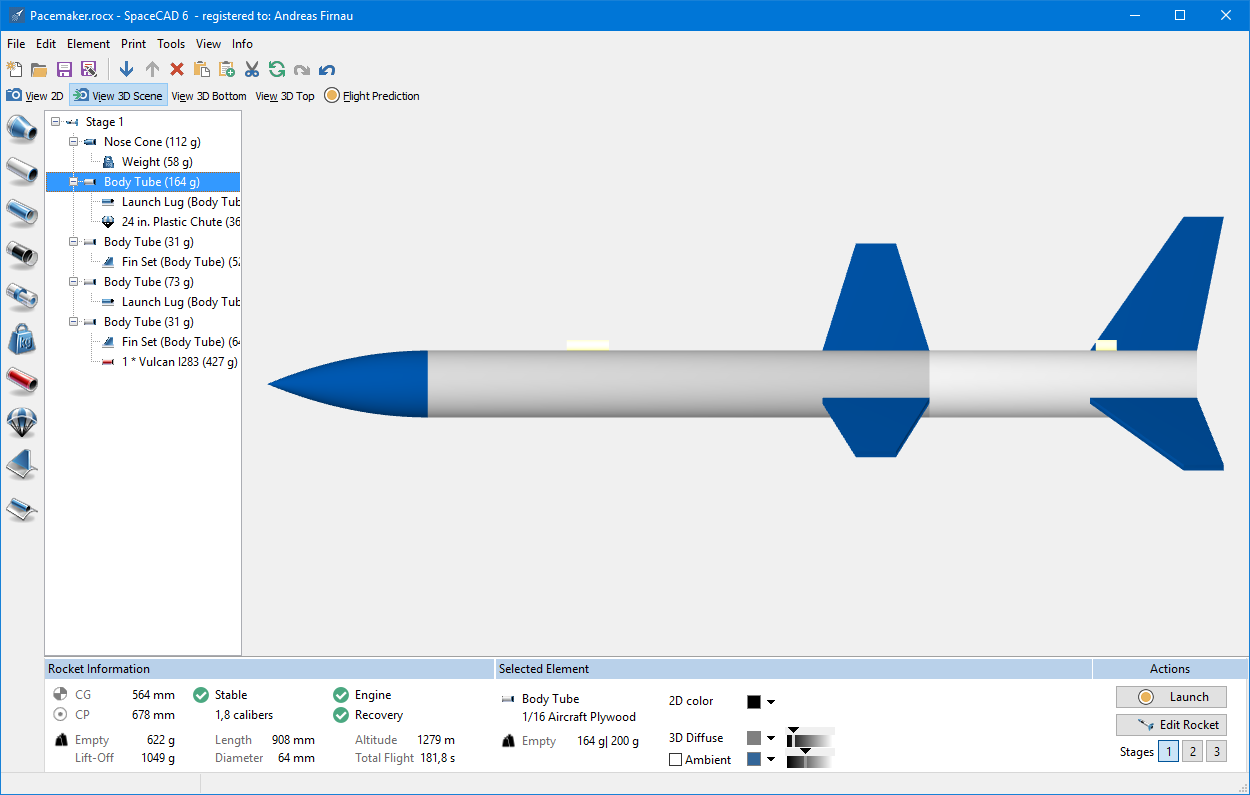

The first design study narrowed the range of the height dimension from 140 mm – 200 mm, to 145.5 mm- 155.5 mm. A set of sensors were used to report area values as the split line changes in height according to a given range of dimensions. The projected area feature was divided using a split line. The use of two design studies made finding the A f and the A b quick and easy. The first method used to calculate the Cp is the “Equal Areas” method, that states the area in front(A f) and behind(A b) the Cp should be equal. When the areas are equal the Cp is located along the center line of the rocket at the reference dimension above the datum. Use of a the “convert entities” sketch command allowed for an extrusion of the projected area. Neither method involves calculus but do require an understanding of the projected area of the rocket’s profile. Fortunately two simplified calculation methods exist for finding the Cp of a rocket. The calculations to properly acquire the Cp of the rocket utilize calculus and the pressure variance of the fluid on the rocket. The Cg for the original design is located 149 mm from the bottom datum of the rocket. The recovery system and motor retaining clip is neglected for the Cg calculation as they are negligible. The motor was modeled as a single body representing the size, and the mass properties were overridden to be that of the real motor. Assembly modeling was used to add a C series motor from Estes. The material properties assign density to the bodies allowing SOLIDWORKS to calculate the mass, and the overall center of gravity. An ABS material was assigned to all the bodies in the part model. The more distance the more stable the rocket, and the inverse to this rule also applies.īecause the design was generated in SOLIDWORKS the center of gravity is easily acquired.

Typically a spacing of at least 1 body tube diameter apart is recommended. The rule of thumb for any rocket designer is to keep the Cp below the Cg (given a rocket in the vertical position). The relationship between these two variables determines a stable or unstable design. Two variables directly affect the stability of a rocket, The Center of Pressure(Cp) and the Center of Gravity(Cg). The stability calculations will be addressed first, as they have a direct effect on the performance of the rocket. The calculations are the basis for the rocket’s stability and performance. As mentioned in “ Rocket Science is Easy“(the previous blog in this series), a set of fundamental calculations need to be completed before the rocket design can be finalized.

0 kommentar(er)

0 kommentar(er)